Mobarakeh Steel. Co. wins 1st place at ACI competition

Mobarakeh Steel’s “Green Concrete Production Using Waste” Project won the first place in Research at the American Concrete Institute (ACI) Competition.

The research project “Production of Green Concrete Using Waste from Mobarakeh Steel Company”, carried out by the University of Isfahan, won first place in the research category at the 27th American Concrete Institute (ACI) Iran Chapter Competition.

Majid Dadjou, Head of Process Waste Treatment at Mobarakeh Steel, announced: “Winning first place in the research category for producing green concrete using Mobarakeh Steel’s waste at the 27th ACI Iran Chapter Competition once again demonstrated that synergy between industry and academia can lead to valuable and impactful results. This achievement is the outcome of combining the scientific expertise of University of Isfahan professors with the collaboration of Mobarakeh Steel’s Process Waste Treatment Unit—a partnership that not only enhances efficiency and creates added value from industrial residues, but also represents a significant step toward developing low-carbon technologies and moving toward sustainable production.”

He emphasized that continuing this constructive collaboration will pave the way for further innovations and transform environmental challenges into industrial opportunities.

Following this achievement, Zahra Heidari, a PhD student in Structural Engineering at the University of Isfahan, stated: “My research focuses on developing green concrete and eco-friendly construction materials using industrial waste. At the 27th ACI Iran Chapter Competition, together with a team of University of Isfahan students, we won first place in the category of environmentally friendly concrete. This reflects the university’s capabilities and highlights the effective role of applied research in advancing sustainable construction technologies. Our other activities also focus on producing green concrete and recycling industrial waste, with a technology-driven and research-based approach.”

She explained the concept and importance of green concrete: “Green concrete refers to any type of concrete in which sustainable substitutes replace Portland cement or natural aggregates—particularly materials derived from industrial waste, mineral residues, or factory by-products. The main goal is to reduce the environmental impact of the construction industry. The importance of green concrete can be summarized as follows:”

Reducing greenhouse gas emissions: Producing one ton of cement releases about one ton of CO₂. By partially replacing cement with industrial waste, carbon emissions can be directly reduced.

Recycling and managing industrial waste: Industries such as steel, sugar, and power plants generate thousands of tons of waste annually. Using these materials in concrete prevents landfilling and creates added value.

Improving technical properties of concrete: Certain wastes, such as steel slag, steel cutting dust, and calcium carbonate sludge, can improve durability, reduce permeability, and increase stability.

Lowering production costs: Industrial substitutes are generally cheaper than cement, reducing the final cost of concrete.

Promoting sustainability and environmental responsibility: Green concrete responds to the global need to reduce the negative impacts of construction and move toward a circular and sustainable economy. It is not only a technical choice but also an environmental and economic necessity for the future of construction.

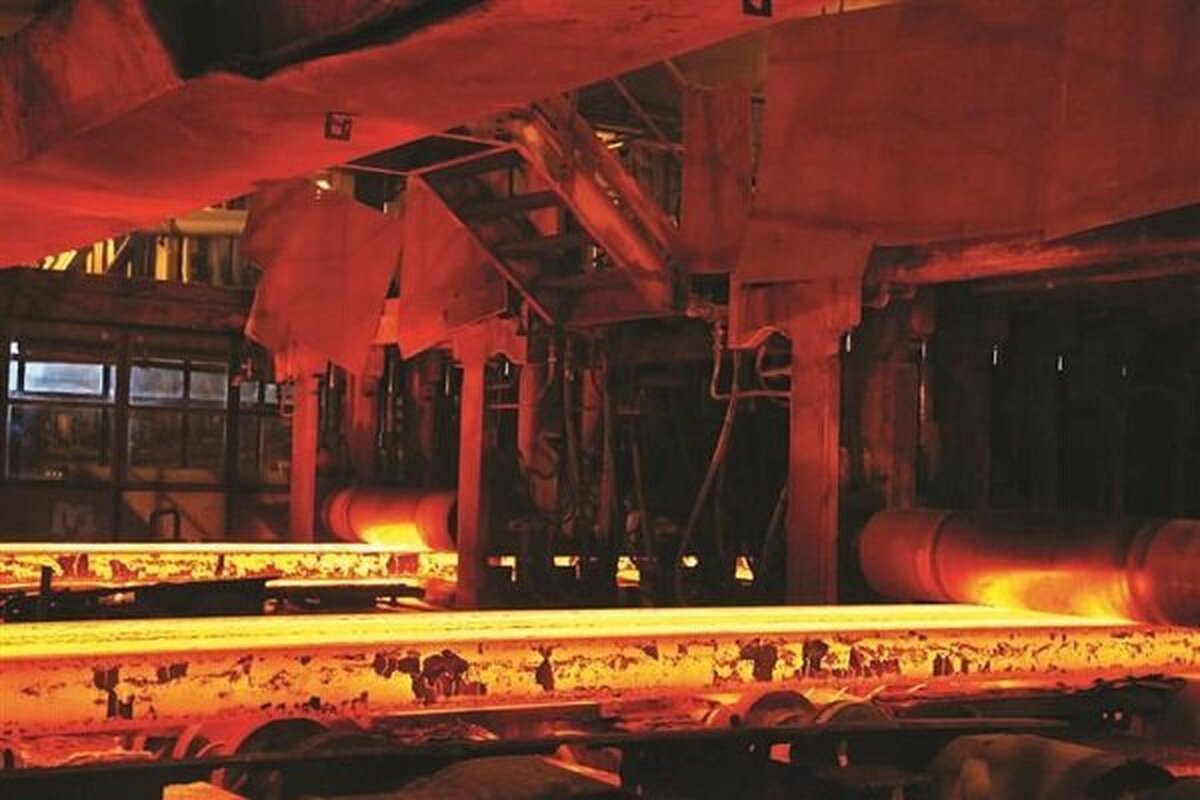

Heidari further explained the project’s design and purpose: “This project aims to convert industrial waste—especially process residues from steel plants, as well as other industrial by-products such as calcium carbonate sludge from sugar factories and stone-cutting waste—into cement substitutes for producing concrete and precast products. The main reasons for implementing the project include: preventing the accumulation of industrial waste and reducing the environmental and economic costs of disposal; creating added value from waste and establishing a circular economy; lowering the final cost of concrete products and increasing industrial competitiveness; and developing local technology while empowering university-industry collaboration for producing eco-friendly materials.”

She highlighted the key benefits of the project:

Sustainable waste management: Reducing the need for landfilling or storage of steel waste, minimizing environmental pollution, and economically utilizing residual materials.

Lower production costs: Reducing raw material (cement) costs and turning a “cost” (waste) into a “resource.”

Strengthening local supply chains: Producing green concrete products with local materials, reducing dependence on imports or heavy cement.

Technological and regulatory achievements: Producing semi-industrial samples and conducting necessary tests for certification, while creating opportunities for showcasing at festivals and attracting industrial partners.

Social and industrial credibility: Enhancing the reputation of Mobarakeh Steel and the University of Isfahan for environmental and social responsibility, increasing attractiveness for investment and further collaborations.

In response to a question about why and how Mobarakeh Steel’s waste was used in this project, Heidari explained, "Steel process residues (such as cutting dust, slags, and other mineral particles) usually contain mineral compounds compatible with the cement matrix. With proper processing (grinding, grading, moisture and impurity control), a portion of cement can be replaced with these materials without negatively affecting concrete performance. In this project, about 20% of cement was replaced with cutting dust in concrete production. The input materials were pre-processed, mixed, and molded, followed by mechanical and durability tests on samples and blocks. Semi-industrial samples were produced and necessary certification tests were conducted.”

She concluded, “The collaboration between Mobarakeh Steel and the University of Isfahan in utilizing process waste for green concrete and circular economy is a prime example of effective linkage between research and industry.”/mehr