What Are the Most Common Gas and Petrochemical Equipment Used by Major Companies?

Major companies in the gas and petrochemical sector rely on an array of specialized gas and petrochemical equipment to facilitate their operations.

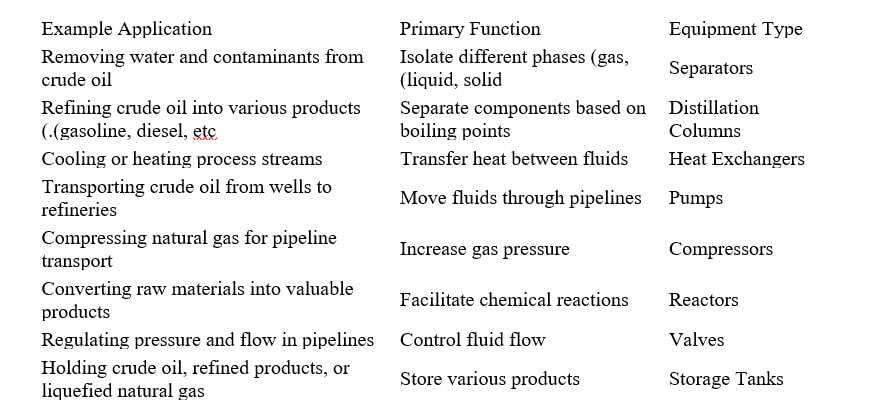

This includes equipment for separation (distillation columns, separators), transfer (pumps, compressors), process reactions (reactors), and storage (tanks). Leading providers, for example Siemens in Saudi Arabia, offer cutting-edge solutions for gas and petrochemical equipment, ensuring optimal performance and safety. These components, along with numerous others, ensure the safe and efficient processing and transportation of hydrocarbons. For further insights into these technologies, consider visiting .the Emaad website.

What are the different types of gas and petrochemical equipment and what are their applications?

Separation Equipment

Distillation Columns: These towering structures employ the principle of differential boiling points to separate complex hydrocarbon mixtures into their constituent components, crucial for refining processes. Leading providers like Siemens in Dubai offer advanced distillation column solutions, optimizing efficiency and product quality for the gas and petrochemical industry. Siemens' expertise in process automation and control further enhances the performance and safety of these critical installations in Saudi Arabia's thriving energy sector.

Separators: These vessels are designed to segregate different phases of fluids, such as oil, gas, and water, ensuring efficient downstream processing. ABB in Saudi Arabia offers advanced solutions for gas and petrochemical equipment, including high-performance separators, to optimize production and resource recovery.

Filters: Essential for removing impurities and contaminants from process streams, ensuring product quality and protecting downstream equipment. “ABB in Saudi Arabia” supplies high-performance filtration solutions for the gas and petrochemical industry, enhancing operational efficiency and product purity.

Transfer Equipment

Pumps: These workhorses of the industry are responsible for moving fluids through pipelines and process systems, ensuring continuous operation. Siemens in Saudi Arabia also provides comprehensive service and support for its pumps, ensuring optimal performance and minimizing downtime.

Compressors: By increasing gas pressure, compressors enable efficient transportation, storage, and utilization of gaseous hydrocarbons.

Valves: These critical components control the flow of fluids, ensuring safe and efficient operation throughout the process.

Process Equipment

Heat Exchangers: These devices facilitate heat transfer between fluids, optimizing energy efficiency and enabling precise temperature control in various processes.

Reactors: The heart of chemical transformations, reactors provide the controlled environment necessary for reactions like cracking, reforming, and polymerization.

Furnaces: These high-temperature units provide the thermal energy required for various processes, such as cracking and distillation.

Storage Equipment

Storage Tanks: These large vessels safely store various hydrocarbons, ensuring product availability and facilitating transportation.

Metering Systems: Accurate measurement and control of fluid flow are essential for process optimization and inventory management.

The gas and petrochemical equipment landscape is vast and complex, with each piece playing a crucial role in the safe, efficient, and profitable operation of this vital industry. Emaad Company is also capable of providing equipment across all these categories, offering competitive solutions and expertise to support the gas and petrochemical industry.

How can the efficiency of gas and petrochemical equipment be increased

Enhancing the efficiency of petrochemical equipment is paramount for optimizing production, reducing costs, and minimizing environmental impact. Several strategies can be employed to achieve these goals:

1. Predictive Maintenance: Implementing predictive maintenance programs, leveraging sensor data and advanced analytics, can help identify potential equipment failures before they occur, minimizing downtime and optimizing maintenance schedules.

2. Process Optimization: Continuous evaluation and refinement of process parameters, aided by simulation and modeling tools, can lead to improved yields, reduced energy consumption, and minimized waste generation.

3. Advanced Materials: Utilizing advanced materials with superior corrosion resistance, thermal stability, and mechanical properties can extend equipment lifespan and reduce maintenance requirements.

4. Energy Recovery: Implementing energy recovery systems, such as waste heat recovery units and heat integration networks, can significantly improve overall energy efficiency and reduce operating costs.

5. Digitalization and Automation: Embracing digital technologies, including the Industrial Internet of Things and advanced process control systems, can enable real-time monitoring, optimization, and remote operation of equipment, leading to improved efficiency and productivity.

6. Operator Training: Providing comprehensive training to operators on best practices and troubleshooting techniques can empower them to identify and address potential issues proactively, minimizing downtime and maximizing equipment performance.

Siemens in Dubai, as a key player in industrial automation and digitalization, provides cutting-edge solutions that enable companies to optimize their processes and achieve greater resource efficiency. Also In your opinion, what is the most crucial strategy for significantly enhancing the efficiency and sustainability of petrochemical equipment?

What are the most important factors influencing the selection of gas and petrochemical equipment?

• Selecting the appropriate gas and petrochemical equipment is a critical decision that can significantly impact the safety, efficiency, and profitability of operations. Several factors must be carefully considered to ensure the optimal choice:

• Process Requirements: The specific process conditions, including temperature, pressure, flow rates, and chemical composition, dictate the materials of construction, design specifications, and performance capabilities required for the equipment.

• Safety and Regulatory Compliance: Adherence to stringent safety standards and regulatory requirements is paramount. Equipment must be designed and manufactured to mitigate risks and ensure the well-being of personnel and the environment.

• Reliability and Maintainability: Equipment reliability is crucial for minimizing downtime and maximizing production. Ease of maintenance, including accessibility for inspection and repair, should also be considered.

• Cost-Effectiveness: While initial capital cost is important, the total cost of ownership, including maintenance, energy consumption, and potential downtime, should be evaluated to ensure long-term economic viability.

• Technological Advancements: Staying abreast of the latest technological developments can lead to the adoption of more efficient, reliable, and environmentally friendly equipment.

• Vendor Reputation and Support: Choosing a reputable vendor with a proven track record and strong after-sales support is essential for ensuring smooth installation, commissioning, and ongoing technical assistance.

Conclusion

In closing, it's evident that the intricate world of gas and petrochemical equipment is vital to modern society. These complex systems and machinery underpin the extraction, processing, and distribution of the hydrocarbons that fuel our world. From towering distillation columns to intricate valve networks, each piece of equipment plays a crucial role in ensuring the efficient and safe operation of this critical industry. As we move towards a more sustainable future, the ongoing development and refinement of these technologies will be paramount in meeting the energy demands of tomorrow.

Companies like Emaad are also contributing significantly by providing the necessary equipment, playing a key role alongside others in this essential industry. In your opinion, What are the most important factors to consider when choosing gas and petrochemical equipment for sustainable operations?